Distributed Power, Cooling, Refrigeration and Heating, all from Waste

The Carbon-Negative Circular Economy

Africa Waste to Energy Limited

The Circular Economy in action

Africa Waste to Energy Limited

We offer affordable zero carbon power, cooling and heating solutions for businesses and communities.

The Circular Economy in action

Africa Waste to Energy Limited

We offer affordable zero carbon power, cooling and heating solutions for businesses and communities.

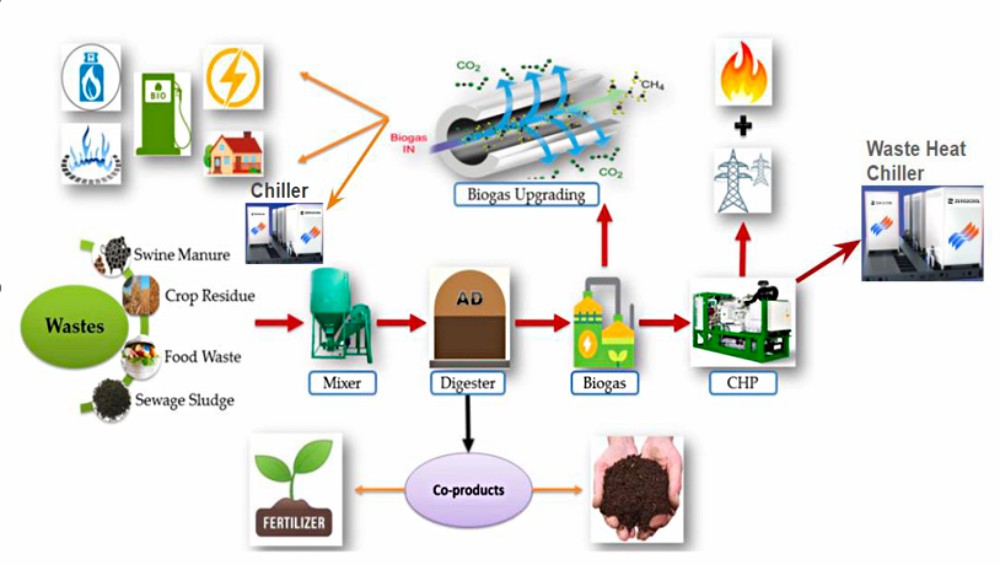

Biogas from Organic Waste

Eliminating reliance on diesel & other fossil fuels.

Zero Carbon Cooling and Heating from Waste Heat

Utilising the “waste of the waste” to deliver vital services.

Challenges we resolve

An Africa-wide problem

Energy access – electrification for all

- 600 million people (43% of the population of Africa) today have no reliable access to electricity.

- Conventional renewable sources of energy – solar, wind, geothermal – will not be the whole answer.

- With Africa’s agricultural economy being so important, there is an abundant potential power source in agricultural loss and waste.

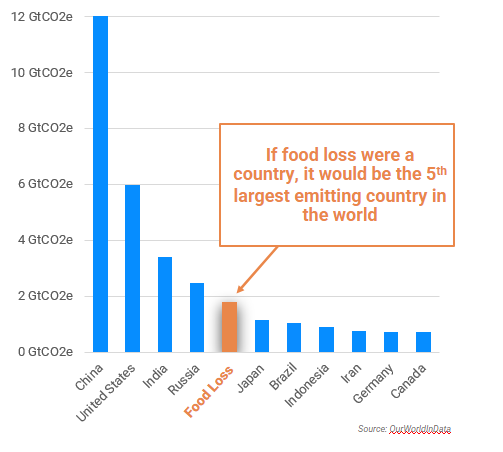

- Today, Africa loses 1.3 billion tons of food every year in post harvest losses, at a cost of over $1 trillion.

- AW2E turns this loss into an energy gain, by generating biogas from the agricultural and market waste

- By using biogas, generated locally where the power is needed, we can provide abundant power to service local needs.

- Not only are we replacing fossil fuels, but we are avoiding the wasteful generation of Greenhouse Gases from the rotting vegetable and animal waste.

- Methane from rotting waste is 80 times more harmful than CO2 in the atmosphere.

The Cold Crunch

- Today, energy-efficient cold chains for perishable food and medicines in sub-Saharan Africa (SSA) are a vital but unaffordable luxury for most people.

- Food loss in supply chains runs at up to 60%, depressing farmers’ incomes, leading to vastly inefficient use of resources, and producing enormous amounts of greenhouse gases.

- Access to cooling is critical to achievement of the UN Sustainable Development Goals, because its absence affects the economy, social life and the climate.

- With access to power through biogas from waste, we can make cooling and refrigeration affordable and accessible where needed.

- With AW2E partner Zero2Cool’s cooling technology, most cooling will be free at the point of use.

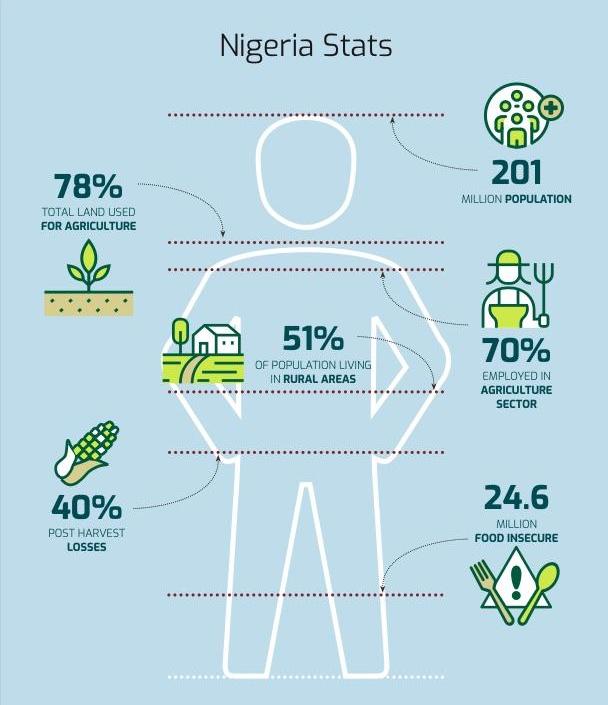

Energy Challenges - Nigeria

- No, or unreliable, electricity supply, especially in rural areas; reliance on diesel generators

- Unaffordability of generator power (diesel price)

- Limited suitability of solar and wind in deployment of distributed power (microgrids)

- Critical services – power for food processing, cooling, refrigeration, hot water – are out of reach for most

- Leading to

- High food loss due to lack of refrigeration and temperature management

- Missing out on value-added food processing (export markets; unnecessary imports of food substitutes)

- Inability to manage supply and demand (higher seasonal price variations; food shortages)

- Food markets failing to maximise storage capacity (failure to serve market need; very high food losses)

- Overall, lower prices and lower quality food products, plus food shortages

- Increased transportation, fertilizer and water costs due to need to replace food lost

- Inefficient use, and long term degradation, of productive land

- These challenges are repeated across much of Sub-Saharan Africa.

Waste to Energy2:

a Circular Economy Solution

Biogas from Organic Waste

- Centralized collection and anaerobic digestion

- Conversion to biomethane for direct power and bottled gas.

Cooling and Heating

- Proprietary waste-heat/biomethane-powered chillers

- Cooling and hot water – free at the point of use.

Sustainable Impact

- Reductions in food loss

- Reductions in overall GHG emissions

- Carbon neutral to carbon negative in power generation

- Job creation and economic opportunities.

Who We Are

Africa Waste to Energy Limited (AW2E) is a British-African company, delivering Circular Economy energy solutions in Africa

Founded by ChillTechnologies, parent company of Zero2Cool Limited, and SDEM UK, sister company of SDEM Erectors Nigeria

SDEM Erectors Nigeria: Over 40-year track record in:

- Energy, infrastructure and industrial construction

- Electro-mechanical Services

- Civil and Structural Construction

- Operation and maintenance of industrial and energy plants.

Zero2Cool®

- Developer and manufacturer of revolutionary cooling and refrigeration technology

- Patented waste heat-driven chillers, delivering cooling free at the point of use

- Deploying in cold chain solutions and building cooling

- Operating in Africa and worldwide.

Why Choose Us

Combined network of expertise in delivery, installation and management of waste-to-energy products and services.

Focus on reducing food loss and waste in agriculture and markets, with local manufacturing and service delivery.

Expanding economic opportunities from farm to market, reducing poverty and carbon emissions

Economic benefits and impact

Biogas System

- Low CAPEX

- Payback period: ~ 1 year

- Zero Carbon electricity for free

- Zero Carbon cooling & hot water for free

- Eliminating reliance on diesel & other fossil fuels

Diverse Revenue Streams

- PAYGO cold room (markets)

- 2-4 X storage capacity increase (increase in storage revenues)

- Reduce losses for market customers; storage as “pay-on-results”

- Bottled biogas/local electrcicity sales

- Liquid fertilizer sales/chemical fertilizer substitution (from digestate after anaerobic digestion process)

Impact

- Food loss reduction & fuel switch = significant GHG reductions

- Food loss reduction = $ impact from more stock to sell (straight to bottom line in food chain)

- Reducing dependance on imported fossil fuels

- Increasing opportunities for higher value export crops & products through access to power & cooling

- Reducing habitat use (and loss) through over cultivation

- Reducing food imports

Projects

Market Waste

Mixed fruit/vegetable waste, biogas power, cooling (PAYGO cold storage), hot water for markets.

Dairy Farms

Biogas power from manure, cooling and heating from waste heat; eliminating reliance on diesel.

Cold Room

Waste heat-powered cold rooms for yam & ginger.

Aquaculture

Water hyacinth feedstock, fish drying and storage.

University Canteen

Food waste for campus power, cooling, hot water and cooking.

Banana Processing

Waste to biogas for ripening chambers and fertilization.

Send us a message

Complete the form below to send us a message: